Teapot Vintage Shui Ping, 150ml, Hong Ni, F1, 60s

75 600.00 UAH

This teapot can truly be called “canonical.” It was made in the 1960s, at the very beginning of the operation of the First Yixing Factory. At that time, the finest Yixing clay available was used. The use of this clay became one of the main factors that defined the “early period” (1958–1977) as a distinct phenomenon, setting it apart from the later stages of the factory’s work.

At that time, the red Yixing clay (Hong Ni) was mined from the Zhao Zhuang deposit and was completely depleted by 1977. This clay is considered the benchmark—the best for brewing tea. It allows you to extract the maximum from the tea, revealing all its strengths and weaknesses. The only competitor to it might be the Yixing Lao Zhu Ni clay, which ran out even earlier, at the beginning of the 20th century.

After the closure of the Zhao Zhuang deposit, the factory switched to red clay from other Yixing deposits, which differed in composition and was significantly inferior in quality. Starting from the 1980s, iron oxide was added to the clay mixture to enhance its color, along with plasticizers and preservatives to shorten the preparation time of the clay for use. This is because the freshly mined clay needs to “rest” for several years to gain plasticity; without this, cracks and deformations can occur during firing.

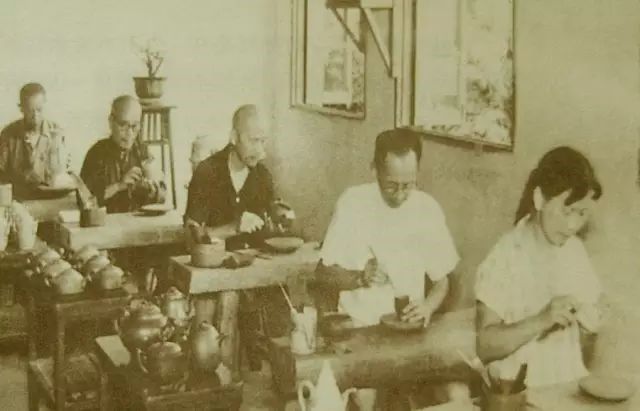

Overall, throughout its existence, the First Yixing Factory moved toward increasing production volumes, which significantly affected the quality of its products. From the very beginning, the masters used a semi-handmade production method, where special templates and molds facilitated and sped up the work. This method is still used by most workshops in Yixing. In the 1950s and 60s, the masters paid more attention to the products, refining the teapot’s shape by hand to meet the set standard. Traces of such manual finishing are clearly visible on early teapots, which look more refined compared to those from later periods.

This teapot is the “standard shape” Shui Ping, which the chief master and founder of the factory, Gu Jingzhou, chose as the base design, making it the most popular shape for decades. The teapot has a volume of 150 ml, or “12 cups” according to the Chinese classification, or “8 cups” by the Taiwanese classification. This is the largest size among the standard ones. Larger teapots were made in smaller quantities and have survived less well to the present day, so they are usually more expensive than smaller teapots.

On the bottom of the teapot, there is a six-digit stamp such as “大溪 / Da Xi,” which is one of the typical marks found on teapots from the early period. In the photo of the stamp, you can see so-called “hidden lines,” which are one of the signs of the teapot’s authenticity. These lines are difficult to see with the naked eye; they are essentially the imprint of micro-cracks in the stone seal that the master used to stamp the teapot upon completion.

This teapot can not only become a true “star” of your collection but also an ideal tool for unlocking the tea’s full potential, an indispensable companion on your journey through the “tea universe.”

In stock

Material:

Country:

Volume:

Master:

Master

First Yixing Factory (1958-1997).

The state-owned factory was the sole producer of Yixing teapots from its founding until the early 1980s. During this time, the factory used the finest Yixing clay available. Skilled artisans worked there, crafting teapots by hand and semi-hand methods. Products from this factory, especially those from the early period (1958–1977), are considered “canonical” among true connoisseurs of Gongfu tea brewing.